Commersald Spa at SAMUEXPO!

We are thrilled to announce Commersald Spa's participation in the prestigious SAMUEXPO fair, the leading reference point for sectors related to tool technologies, mechanical processing, and robotics.

At the Commersald booth, you'll have the opportunity to discover our excellent range of consumable materials under the KOY brand, renowned for their reliability and superior performance. Furthermore, you can experience firsthand the quality of our welding accessories, crafted to meet every need in the field of metalworking.

Our team of experienced technicians will be on hand to welcome you, answer your questions, and share the latest updates in our industry.

Don't miss the chance to explore the innovative solutions from Commersald Spa at the SAMUEXPO fair!

We look forward to meeting you at Pavilion 2, booth number 30.

Robo340, the new robotic island from Commersald Impianti

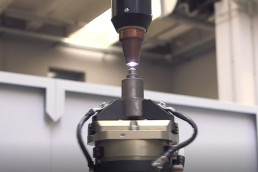

Reliability, innovation and exceptional performance are the basis of Robo340, the new robotic island from Commersald Impianti, tailor-made for valve welding in the Oil & Gas industry!

This cutting-edge Cartesian axes system is driven by numerical control and allows the welding of valves ranging from 18 to 48 inches. Among its key features:

- Double rotary table

- 8 axes

- Double powder feeders

- Maximum load capacity of 6000 kg for each of the rotary tables

Robo340 is ready to set new standards of excellence in industrial automation, delivering highly advanced and customized welding solutions to meet the unique needs of the Oil & Gas industry.

Want to learn more? Contact us now!

Schweissen here we’re!

Schweissen here we’re!

Until September 15th, you can find us here.

Our experts are waiting for you to introduce the latest innovations in:

- PTAW and laser cladding systems with powder and wire

- Consumables for precise and durable welding in any condition

We are at booth A12 in hall 6. Don't miss it!

New edition of Schweissen & Schneiden

All set for a new edition Schweissen & Schneiden.

We are just a few days away from the most important event in the welding techniques industry, which Commersald will be participating in as a group.

Commersald spa and Commersald Impianti will showcase the latest innovations in consumable welding materials and our PTAW and laser cladding systems with powder and wire, which successfully used in different industries such as glass processing, automotive, pipe manufacturing and chemical industry.

Our technicians and sales representatives look forward to meeting you from September 11th to 15th at the Essen trade fair, booth 6A12 in hall 6.

Come visit us.

Cobalt Alloys as filler material for plungers in the glass industry

Introduction

When it comes to glass, the first thing that pops to mind is definitely the finished product. We are therefore talking about bottles and glasses for food and beverage, perfume bottles, pharmaceutical and injectable containers and so on. When it comes to the welding in glass, however, only the few interested and experts in the field are able to recognize the importance of this process that, despite representing a tiny part in the entire cycle of creation of the artifact, directly and decisively affects productivity in the glass factory.

The Challenge

Nickel based alloys (Ni Cr B Si) with hardness from 30HRC to 60HRC have always been the natural choice for hardfacing, especially plungers for glassworks. Historically then, the deposition of these powdered alloys has always been done by means of the oxyacetylene flame (OFW) or because of the process called High Velocity Oxigen Fuel (HVOF). However a major Italian bottle manufacturer contacted us to try to solve the problems of high temperature erosion at which their plungers coated in Nickel were subject during the operating times; therefore it has been suggested the use of Cobalt based alloys, more tender and workable but at the same time much more resistant to high temperatures.

Solution

The problems of using such cobalt-based alloys were mainly related to their high melting temperature (1375-1400 °C). In fact, this temperature was very close to that of the fusion of Cast Iron and Steel and, if a welding was carried out with OFW or HVOF, the base material would also be melted during the remelting process typical of the two processes.

The Benefits

The transition to Transferred Arc Plasma (PTAW) technology with Cobalt powder filler material has led to several advantages not only in terms of workpiece performance that from an operating time of about 92 hours (Nickel) has increased to 325 hours (Cobalt) but also on the productive level in general and, therefore, economic. First of all, it was no longer a layer of molten powder projected towards the metal as was the case with the OFW and HVOF methods, but a total metallurgical anchor that solved the critical issues related to the cooling of the piece itself. In addition, the volume of powder deposited and thus the percentage of dispersion with PTAW technology plummeted from 70% (HVOF) to 3-5% while maintaining the same depositing time – about 5 minutes.

The Testimony

Thanks to the resolutive intervention of our technical staff and the performance offered by our ROBONEXT P (PTAW) plant , the bottle manufacturer was able to solve the problems of high temperature erosion at which their plungers were subject in operation, greatly reducing downtime and lengthening the life times of the plungers themselves.

Commersald supports the Cooperative Madrugada Project

Commersald supports the Cooperative Madrugada Project

The goal of the project and its founder, Roberto Corrocher, Emeritus Professor of Internal Medicine at the University of Verona, is to establish a cooperative composed of local professionals, including medical personnel, nurses, technicians, teachers, and agronomists.

This training project aims to become a genuine laboratory for professional and social empowerment, fostering the development of a new conscious community equipped with models and tools for growth.

The project revolves around four fundamental points:

✔️ OPENING OF A PROFESSIONAL TRAINING SCHOOL

✔️ COMPLETION OF HEALTH SERVICES

✔️ LAUNCH OF AN AGRO-FOOD PLAN

✔️ COMPLETION OF THE SCHOOL CYCLE AND OPENING OF A SPORTS FACILITY

✔️ OPENING OF A RESIDENCE FOR VOLUNTEERS AND ECO-SUSTAINABLE TOURISM

Commersald had long wanted to contribute to a charitable initiative. The Cooperative Madrugada project immediately appealed to us due to its focus on children, who represent our future worldwide, and because of the practicality and structure of the project aimed at creating an autonomous community with significant social reference points.

We are aware that our contribution is modest, but we have great confidence in the potential of the project and the possibility that the collaboration established will be long-lasting and continue to grow year after year.

Commersald Impianti presents the new robotized islands with Laser Cladding!

Commersald Impianti presents the new robotized islands with Laser Cladding!

The range of robotized islands with Cartesian axes controlled by Numerical Control is expanding with new models based on the new Laser Cladding system, in which the power of the laser source and axis dimensions can be customized to meet your specific needs.

Thanks to Laser Cladding, precision and technological advancement come together, allowing you to achieve results that were previously.

SamuExpo 2022

Commersald will be present at SamuExpo, Pordenone/Italy from 31 March to 02 April 2022, reference trade show in the tools and technology sector for metal workings, mechanical and robotics.

We will introduce you our range of special welding consumables and some other complementary products, furthermore our robotized cartesian cladding systems with PTAW and LASER powder technology.

Come to visit us at Hall 3 booth 10 where our technical staff wil be glad to welcome you.

WNE World Nuclear Exhibition 2021

Commersald Impianti will participate in the WNE World Nuclear Exhibition 2021, Paris Villepinte from 30 November to 02 December 2021.

The latest news on cladding with wire and powder superalloys will be present, in particular we will present our proven robotized systems with Cartesian axes P.T.A. Plasma Arc Transfer and the new cells for Laser cladding.

Come and visit us at stand F17!

Koy Clean Plus

Koy Clean Plus is the professional pickling, passivation and polishing system designed for companies that need high productivity, the ideal solution for the instant ecological treatment of TIG, TIG welds with material addition, MIG / MAG, MIG pulsed arc, laser, resistance, orbital, plasma. The inverter technology guarantees a real and constant efficiency of 90%. In addition, the machine is equipped with a blow torch (patented) for the abatement of vapors and automatic delivery of the electrolyte connected, by means of an automatic pump, to the pickling solution tank with indicator of level.

It is possible to connect a second torch (patented) with built-in manual dosing tank, capable of working simultaneously with the large torch, doubling productivity and allowing you to reach the less accessible points more comfortably.