Cobalt Alloys as filler material for plungers in the glass industry

Introduction

When it comes to glass, the first thing that pops to mind is definitely the finished product. We are therefore talking about bottles and glasses for food and beverage, perfume bottles, pharmaceutical and injectable containers and so on. When it comes to the welding in glass, however, only the few interested and experts in the field are able to recognize the importance of this process that, despite representing a tiny part in the entire cycle of creation of the artifact, directly and decisively affects productivity in the glass factory.

The Challenge

Nickel based alloys (Ni Cr B Si) with hardness from 30HRC to 60HRC have always been the natural choice for hardfacing, especially plungers for glassworks. Historically then, the deposition of these powdered alloys has always been done by means of the oxyacetylene flame (OFW) or because of the process called High Velocity Oxigen Fuel (HVOF). However a major Italian bottle manufacturer contacted us to try to solve the problems of high temperature erosion at which their plungers coated in Nickel were subject during the operating times; therefore it has been suggested the use of Cobalt based alloys, more tender and workable but at the same time much more resistant to high temperatures.

Solution

The problems of using such cobalt-based alloys were mainly related to their high melting temperature (1375-1400 °C). In fact, this temperature was very close to that of the fusion of Cast Iron and Steel and, if a welding was carried out with OFW or HVOF, the base material would also be melted during the remelting process typical of the two processes.

The Benefits

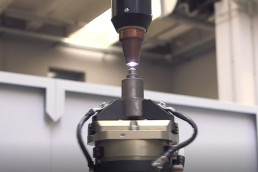

The transition to Transferred Arc Plasma (PTAW) technology with Cobalt powder filler material has led to several advantages not only in terms of workpiece performance that from an operating time of about 92 hours (Nickel) has increased to 325 hours (Cobalt) but also on the productive level in general and, therefore, economic. First of all, it was no longer a layer of molten powder projected towards the metal as was the case with the OFW and HVOF methods, but a total metallurgical anchor that solved the critical issues related to the cooling of the piece itself. In addition, the volume of powder deposited and thus the percentage of dispersion with PTAW technology plummeted from 70% (HVOF) to 3-5% while maintaining the same depositing time – about 5 minutes.

The Testimony

Thanks to the resolutive intervention of our technical staff and the performance offered by our ROBONEXT P (PTAW) plant , the bottle manufacturer was able to solve the problems of high temperature erosion at which their plungers were subject in operation, greatly reducing downtime and lengthening the life times of the plungers themselves.